Location: Ireland

Industry: Cable and Wire Harness

Services Offered: Odoo Consultancy, Odoo Implementation, Odoo Configuration, Odoo Development, Training

Odoo Applications: Contacts, Sales, Accounting, Purchase, Inventory, Manufacturing, Quality, Barcode, Repairs, Product Lifecycle Management (PLM), Sign, Employees

Applications Replaced: Access Supply Chain ERP, ReadSoft Software

Hosting & Edition: Odoo Sh Enterprise

Implementation Timeline: 2 months

About Alida Systems

Alida Systems is a company based in Ireland, popular for manufacturing electrical cables. They manufacture cable harnesses, supply contract equipment, and box-build panels. They are renowned wholesale dealers of cable and wire harnesses across automotive, security, health care, telecommunications, defence & aerospace and commercial cabling sectors.

Challenges

Inefficient Systems -

Alida Systems used an ERP called Access Supply Chain to handle their day-to-day operations. While the system helped for a basic level management, it couldn't handle the production or manufacturing data in a full-fledged manner.

The company still used paper-based orders, printed drawings, and related documents. It led to data inconsistencies and mistakes that hampered all other business processes, plus it was extremely time-consuming to document all vital information on paper.

Lack of a Product Life Cycle Management Platform -

During manufacturing, the team had to examine the products manually and pass them to the next stage. Their existing ERP was not capable of handling the associated data. Moreover, there was no segregation or clarity on how the processes were handled in each stage.

For example, when the company receives an order, it would have specific order components and operations. There would be a bill of materials, work order, and manufacturing order documents.

As their ERP was inefficient, several data discrepancies crept in along with some problems:

- The process of preparing products as per the orders became time-consuming.

- Adding, modifying, and updating data was difficult, leading to manufacturing delays.

- Paper-based documentation was a big problem while manufacturing complex parts.

Solutions

Comprehensive Data Management with Odoo ERP -

Emipro helped Alida solve data management issues by offering an integrated Odoo system to help them manage their production, manufacturing, and accounting information.

They didn't have to depend upon paper-based work orders or data-entering practices. Odoo provided the company with the following benefits –

- Capturing data for time recording and making calculations

- Consolidating all the information under a single platform

- Sharing information across multiple departments

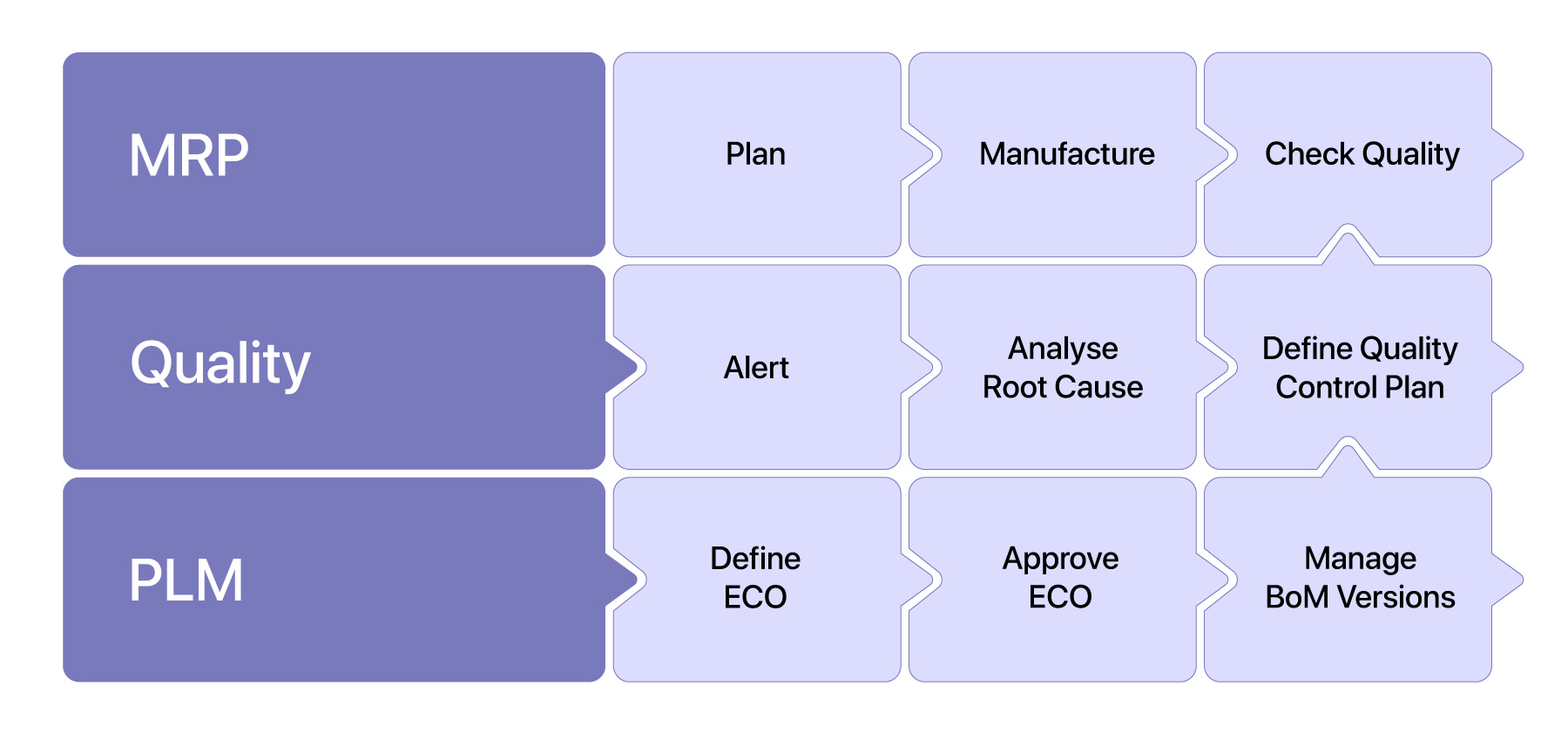

A Streamlined PLM System for Better Manufacturing Processes - When Odoo was implemented for Alida Systems, Emipro developed a streamlined PLM system for manufacturing orders. Product Life Cycle Management is important for –

- Improving manufacturing efficiency

- Evaluating stages

- Preparing project schedules

- Maximizing profits and reducing wastage

The different Odoo features that helped Alida are discussed below:

- Bill of Materials -

The bill of materials is a document that includes data about the raw materials and components needed to develop a product. Without it, managing product development requirements and expenses is challenging.

However, as the new PLM module offered a bill of materials, handling product information was smoother. The entire team was on board with the project requirement and expenses. - Manufacturing Orders (MO) - Manufacturing orders (MO) are built to define a product with components required in it.

The different details specified under MO are – - Components which included hardware raw materials

- Operations such as labeling, prepping, final assembly, and testing

- The MO helped access the project/product data quickly and understand the component quantities.

- Work Orders (WO) - An MO is the parent record on Odoo, and work orders are its child records. Work orders define the manufacturing stages any product is divided into and its corresponding operations.

These work orders helped Alida employees to manage project data, deadlines, labor and expenses efficiently. - Work Centers - Work orders define each manufacturing stage as work centers. These included stripping, soldering, machine crimping, and final assembly, which were departments in the factory. Moreover, the operations corresponded to these stages.

With this feature, professionals could establish project completion timelines and track each stage's progress.

Importance of Time Duration and No of Component Units Mentioned In MO and WO - Through the Reporting feature, Odoo enabled users to track the various aspects of work orders and manufacturing orders.

- Time duration – Helped understand the time taken for completing a stage.

- Number of component units – Defined the different unit amounts needed for each stage.

It provided better clarity on the project’s progress and deadlines, which was not possible earlier.

Improved Solutions to Manage Accounting and HR Documentation - Odoo had excellent accounting functionalities to store financial information. Inventory valuation, invoicing, taxation, data importing, and online bank reconciliation facilities were available on the platform.

Impact & Benefits

Alida Systems improved its B2B sales and order management through effective Odoo integrations and solutions –

- Better order management – Handling manufacturing orders, storing associated information, and executing stages efficiently was possible.

- Improved product life cycle management - Better PLM resulted in faster product manufacturing, deployment, and revenue collection.

- Streamlined accounting solutions - They no longer depended on spreadsheets and used Odoo for invoicing, taxation, and preparing HR/Admin documents.

- Increased operational efficiency – Alida got a better view of their data on a single platform, boosting their efficiency.

Conclusion

Thus, Emipro's services allowed Alida Systems to enhance business efficiency and synchronize various processes.

Emipro – your trusted Odoo Gold Partner for retail ERP transformation.

👉 Looking to solve similar challenges? Connect with Emipro, the leading Odoo Gold Partner in India.