Going back to past, in a large organisation, things were often supposed to go out of the control for inventory management. As we know, on daily baises, it's supposed to have numerous transaction related to inventory, whether raw material transferred to production location, or consignment shipped to customer. All things are supposed to be recorded manually on paper, and at the end of time, there has to be tally of inventory.

And here comes Murphy's law! Bunch of people always keep finding the difference into inventory and tries to match real figure with the expected one. Not only it was time consuming, but like many cooks spoiling the broth, calculation done by many people very seldom come out with accurate figures! It was a real mess. Management were never had a 100% right figures regarding what is supposed to come in, and what is supposed to go, from where and when? Above all these, there was a huge fear of inventory being stolen, and you never come to know about that, as it was helping to match the real inventory with expected figures! Things were as such that management many times does not get actual figures of real inventory count as they were written on different papers, on different places. ( May be I am sharing you one of the actual project defination which we have recently accomplished. Don't tell my mother that I am sharing the actual Odoo project requirement publically ;) )

Coming back to the future, invention of computer made life somewhat easy for companies. Records being stored in spread-sheets, and with internet arrived, there as all the access of all the details, helping management to take right decision on right time. Not only this, but than after came concept of ERP, and many software designed including that concept.

Life after ERP, not too bad. (or not too good !)

Organisations started to believe that finally things will be in control, but it came with different kind of challenges. Though it was better than previous scenario, as there is always scope of improvement into ERP. Let's first see some of the bright side of it.

Fixing Responsibility

With centralised system in place, (Let's say Odoo) all the related data are placed into it, like for sales, purchases or manufacturing. Warehouse users are also supposed to count all the related inventory and insert those details into very same system. Variations are expected, but here what we can do, is measure performance of each one. For example, based on ratio of variation for certain time being, we can either appraise employee or can fire them! But here one thing is certain that employee cannot escape from their responsibility.

Easy to get valuation of your Inventory

There are many methods are available to calculate valuation of inventory in company, and with the use of ERP, at each and every point of time, system is supposed to manage inventory related accounting details as well. And when management requires those details, they can get from system. And as we know that there are many kind of cost are related to inventory, like purchase cost, holding cost, etc. With having the right details, those cost can be reduced.

Unrealized profit calculation, how it helps

This is very important thing. Let's go through an example, with one purchase of inventory. Now company expect some sale price of that and than deduct real cost from expected sale price. This is how they get some unrealised profit. Yes, it's not real one, but based on those data, they can have some idea that how much they are expected to earn from that inventory. And as time goes pass by they can determine, they do they need such product or not.

What is to expect from ERP to have, to easily calculate inventory into it ?

One can directly comes up with very first answer, is to have easy interface to enter data. While in large organisation, it's obvious that location to hold inventory will be also very large. For that following things are expected for inventory to have.

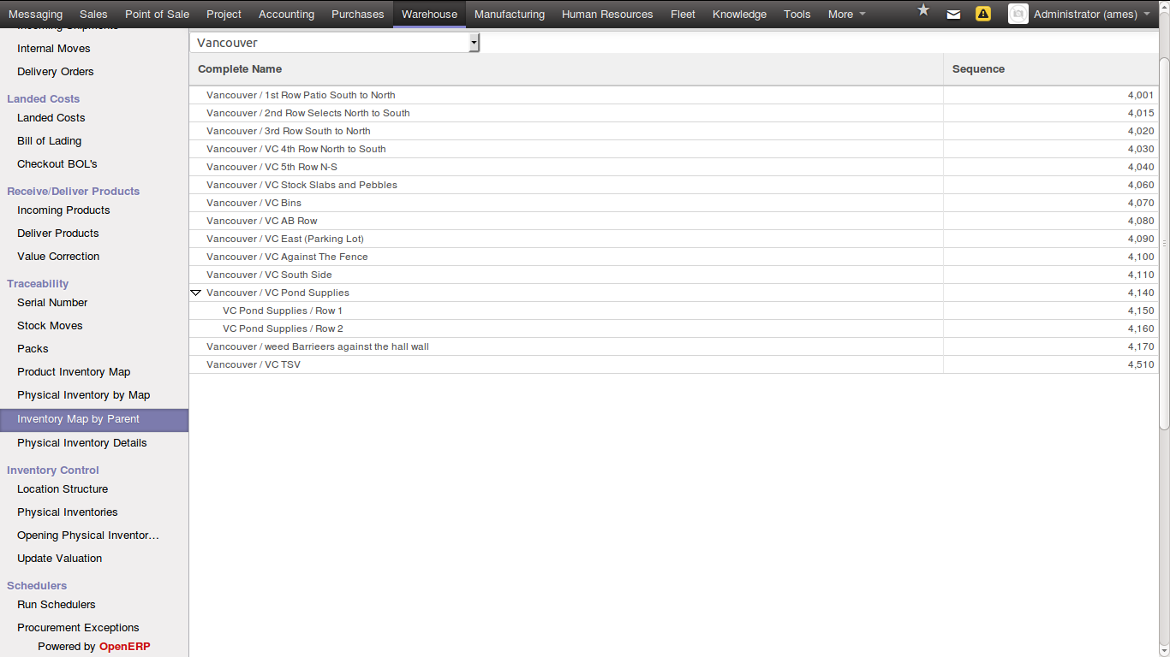

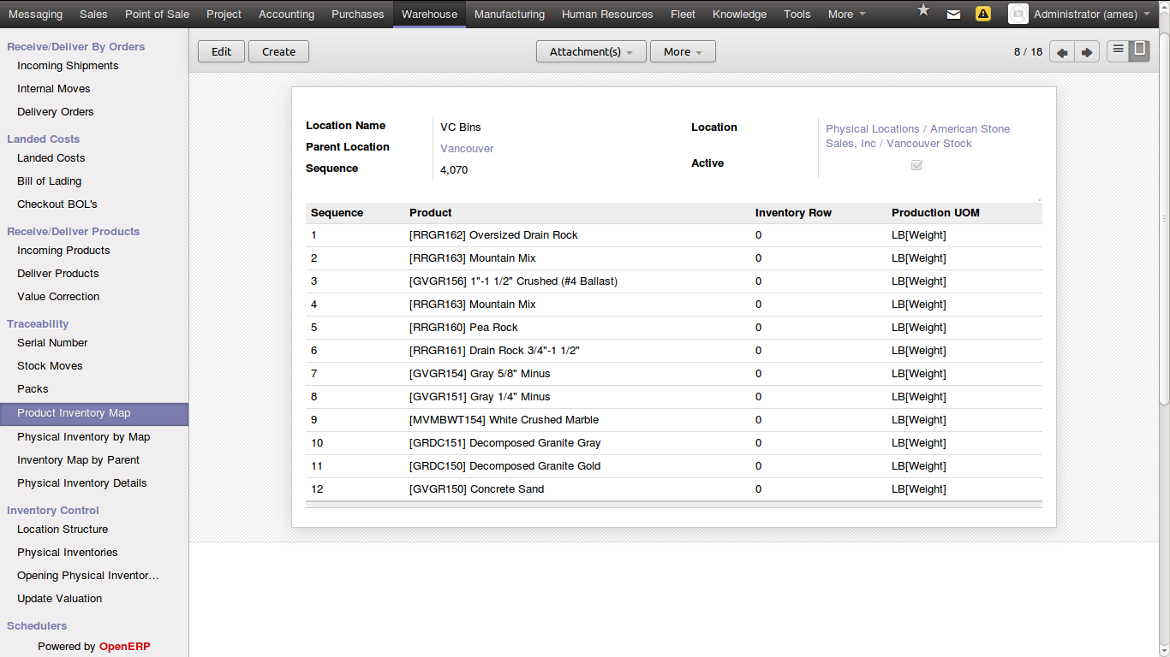

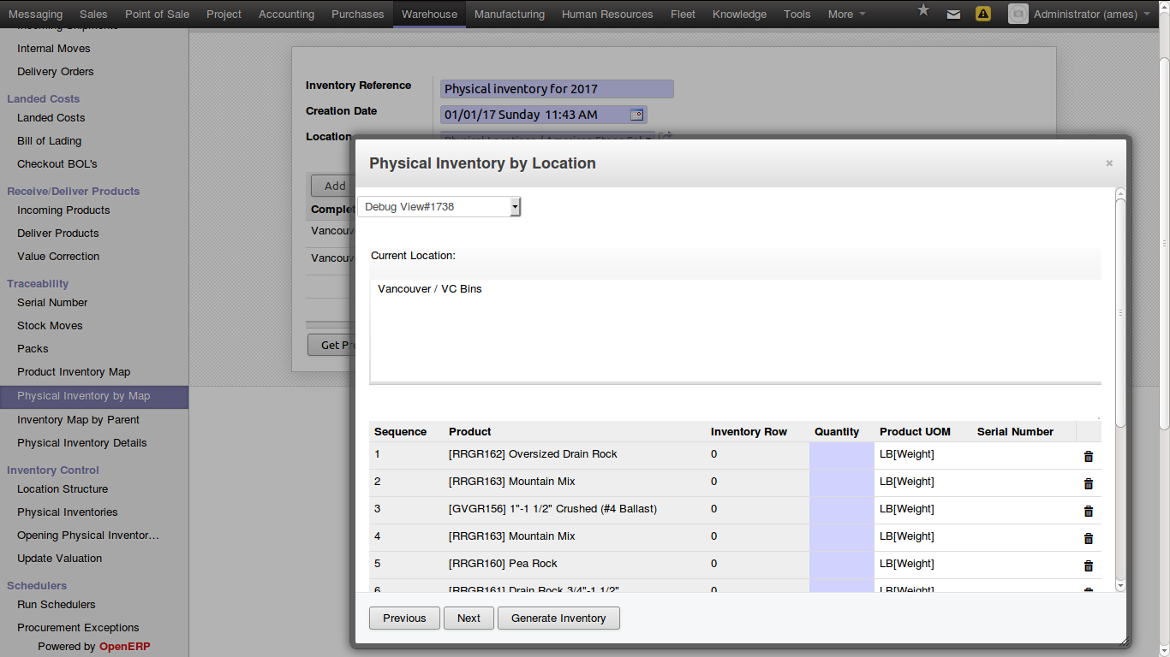

Prepare Inventory Map in ERP

In organised sector, there is virtual map of all product inventory. They should expect to have such configuration in ERP where they can configure such map, based on their requirement. By having such thing, it will have very same interface as actual one, and will help user to enter data. And there will be less chance to have wrong information in system. Expanding above thing, for each location, there is pre-marked location for each product. Here we can also manage that attribute while preparing such map. For different location, place of one product will also be different, so to manage such thing in ERP will make life somewhat more easy to end user. ( Below are few examples of Inventory & Product Map concept in ERP system )

#Fact : We are among only few who has implemented/invented Inventory Map concept so far in entire Odoo ERP Community.

Location wise inventory

In company, one product moves to many location, from one warehouse to another, and from one location to another location. What is important in such case for management to have data that in which location, how much inventory are there. Like currently how much inventory are there currently in production location, and from that consumption, how much is expected out come, will there be any inventory loss ? If yes, than what will be approx percentage of that. By having such calculation in place, it becomes much easier for the management for better analysis of stock level in organisation and forecast the future stock needs according to that.

While those were some of the good things, there were quite issues as well. Let's check those as well, and understand how to overcome those.

No inventory in ERP, while it's there in actual stock

Many time, such things happens that real inventory is there in location, there is a sales delivery waiting to deliver, but you cannot move ahead in system, because there is no stock available in ERP, at that time if you try to force deliver, it will trigger a collapse, and than it will be too hard to get real amount of either stock on hand or valuation! So it's very important that one should enter data into system, as quickly as possible.

Irregularity in following of schedule

This is also one of the point, which should be taken care of. Based on requirement, there has been some priority assign to production chain. And production department has to maintain that. Because based on that future purchase (or sales) related planning has to be made. Now, if production moves outside of that chain, than related inventory management will also go out of the bound. And all the things will mess-up. So unless there is some support is available, one should not brake such chain.

For many time, inventory is such a point, which is not given that much weight-age, and it's taken for granted. But as time goes, lack of inventory management hurts as badly as one could not imagine ! There was a time when things were very complicated to mange manually, but after the evolution of ERP, thing have become better. And it will only give you best possible result, if process of it been followed strictly and effectively. Otherwise company will have a loss of time and money, and will go back to stone age!